Cement foaming agent, also known as foaming concrete foaming agent, refers to an admixture that can reduce the surface tension of liquid and generate a large amount of uniform and stable foam for the production of foamed concrete. Foaming agent is a kind of substance that can make its aqueous...

The Property And Application of Nano Silicon Powder

What are the properties of nanosilica powder?

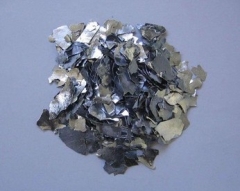

Nano silicon powder The term crystalline silicon is used to describe particles that are less than 5 nanometers in diameter (one billion (1G), of a meter). The characteristics of nanosilicon powder are high purity and uniformity. This product is nontoxic and tastesless because of its large surface, high surface activity as well as low bulk density. Nano silicon is a new type of optoelectronic material with high energy semiconductors. It is also used as a light source.Nano-silica powder can be prepared using the gas phase laser with variable current. It has high product quality, a good dispersion ability, small particles, uniformity, a large surface area, heightened surface activity, low density, good activity and scalable industrial output.

How can nano silicon powder be used?

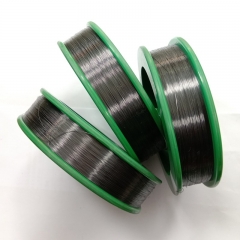

1. You can use nanosilicon powder to make nanosilicon wires in the negative electrode materials of rechargeable Lithium batteries, or you can use graphite as the surface material on nanosilicon powder, increasing the capacity and number of charge-discharge cycling of rechargeable Lithium batteries by 3 times.2. It is used as a raw material for organic silicon polymer materials and high temperature resistant coatings.

3. Nanosilicon powder is applied to coatings in order to form a thin, film-like layer of nanosilicon particles. This technology is used widely for solar energy.

4. The nano-silicon carbide--diamond composite is formed by mixing the silicon powder with diamond under high pressure. It can be used as a tool for strength and toughness.

5. The theoretical specific capacity of nano-silicon for lithium-ion cells is 4200mAh/g, which is higher than the carbon material.

6. On the nano-silicon surface, ten different nano-silicon structures are designed. These nano-structures can be used to produce photoluminescence for the main wavelength ranges from near UV to near Infrared as well as low threshold voltages electroluminescence.

Tech Co., Ltd. is a professional nano silicon powder Over 12 years in research and development of chemical products. You can contact us for high quality silicon nano powder. Contact us Send an inquiry.